Quality,Cost,On-Time Delivery

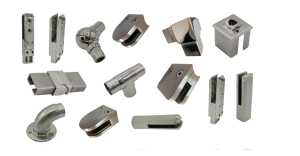

No matter how the demand of customers vary, they always come down to the basic 3 factors-Quality, Cost, On-time delivery. As an OEM manufacturer for architectural hardware metals, we always seek to maximize our performance on these 3 factors and supply reliable glass railing&handrail fitting products to our customers.

Quality-How is the quality guaranteed?

- In-house Production

Works are done in our fully-owned Lost-wax casting , machining and polishing surface treatment production lines.

- 100% inspection at critical steps.

We apply 100% inspection through casting, machining, surface treatment processes and packaging processes.

- Process Quality Stability

Inspection is a necessary means to control quality but we also recognize the fact that Quality is not only a result of inspection but also an outcome resulting from the process stability, where we invest equal amount of input as we do with inspection.

- Production process certification

Stringent Process Documentation and ISO 9001:2015 Certification by TÜV Rheinland with annual audit requirements.

- Responsible Defect Handling

Despite of the low occurrence of defect products delivered, Upon confirmation that defect products are delivered, we take immediate action for the corresponding product replacement.

Cost-How is the cost maintained competitive?

- Process Cost Efficiency and Effectiveness

We seek to maintain maximal quality performance at any preceding production step, which thus minimizes rework and repetitive resource input needed at later stage to achieve maximal cost efficiency and effectiveness.

- Core Processes Streamlined in One Location.

The first 3 core production processes(casting,machining&surface treatment) are done in our own factory in one location. Thus, unlike companies with only 1 or 2 of these processes, We minimize transaction cost in money or time terms from potential outsourcing of the above processes and do not pass cost incurred from outsourcing to our customers.

- Economies of scales

With a strong focus on Architectural hardware metals and the current volume in our daily production, we can achieve long-term economies of scale in production, thus applying a competitive pricing for our customers.

Lead-time&On-time delivery-How are they controlled?

- Lead time

Sampling:Tooling Manufacturing: 15-18 days. Samples Production is 15-20 days.

Serial Production: Casting 15-20 days, machining 10-15, Surface Treatment 10-15 days.

*Depending on actual order quantity. Days inclusive weekends and public holidays.

- Production Scheduling

Our production scheduling is organized by a master scheduling department, which oversees and coordinates production scheduling and progress in shopfloor on a daily basis to maintain satisfactory on-time delivery rate with our customers.

- Inventory Agreement

In some cases, upon agreement, we support our customer to shorten their lead time and undertake a % of inventory in regard to their sales forecast.

Professional Architectural Hardware Metal Manufacturer

For Stainless Glass Railing&Handrail Fittings Since 2004

Address: No.12,Linqing Road,High-tec Industrial Development Zone,257081,Dongying,Shandong Province, China

Tel: +86 (546) 8180566| M: +86 17605462118 | FAX: +86 (546) 8251668

E-mail: info@kelinmachinerytech.com

Web:www.kelinmachinerytech.com